Search

Located in the northern part of Doha, Qatar's capital, the lusell stadium, which can accommodate 80000 seats, is the main stadium of the 2022 World Cup in Qatar. It will undertake important activities such as the opening ceremony, final and closing ceremony, and will become an international landmark building in Qatar after completion.

There are 92000 seats in the stadium, 1000 more than the bird's nest. The construction of lusell stadium is quite difficult. The main body of the venue is a steel beam combined with concrete structure, with a steel volume of 100000 tons and a membrane structure of 45000 square meters. It is the largest membrane structure in the world at present.

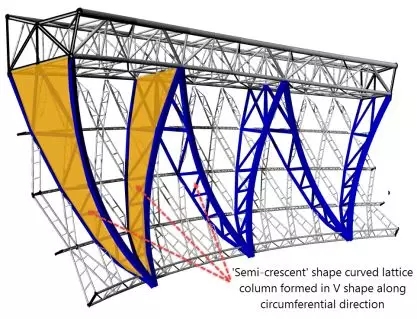

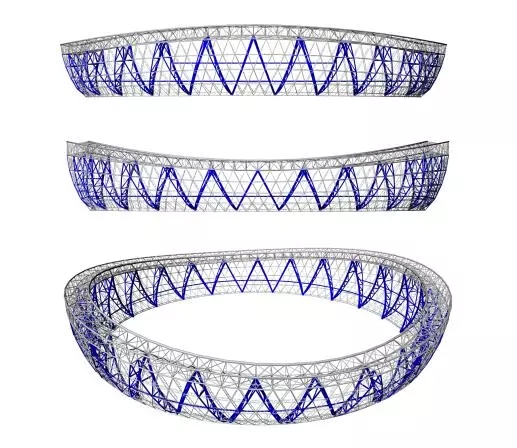

The shape of lusell stadium is like a huge "golden bowl". The total steel consumption of its main body and stand steel structure is about 30000 tons, equivalent to the weight of three Eiffel towers. V-pillar is an important part of the main steel structure of the project, with a total weight of about 6271 tons. It is the main vertical force transmission system of "golden bowl", which provides support for the compression ring and the side wall structure of curtain wall, and transmits the vertical force to the concrete column pier, and then to the ground.

Among the two enterprises that won the bid for the project, the other is China Railway Construction Co., Ltd., in addition to HBK, a local Qatar construction company. Russell stadium is the first world cup main stadium built by Chinese enterprises as a main contractor. The total contract value of the project is 2.8 billion QAR, about 5.17 billion yuan, about $767 million. China Railway Construction accounts for 45%. The total construction period of the project is 40 months.

The lusell stadium project should not only meet FIFA's specifications, but also meet European and American specifications and Qatar's local specifications. The project also involves dozens of third-party enterprises such as Australian Aurecon, British AFL and Vietnam Aurecon company, which can be called a world cup competition of construction. Since the commencement of construction, China Railway Construction and Qatar HBK company have formed a close joint venture to coordinate and lead the construction teams of various countries, use a large number of scientific and technological innovation achievements, overcome the problems of high temperature and humidity, complex process, cross construction, etc., and make the project move forward steadily.

"V" ratio of one hundred ton steel structure for construction of important joints

On May 10, 2019 local time, the first single v-pillar of the 2022 Qatar world cup main stadium lusell membrane structure stadium project undertaken by China Railway Construction Corporation was successfully hoisted, marking a major breakthrough in the construction of steel structures controlling key factors of the construction period.

What about the v-pillar? Let's take a picture

There are 48 single v-pillars in the project, with a total weight of about 6271 tons. The single v-pillar lifted this time has a weight of about 147 tons, a length of about 48 meters, and a top width of about 15.5 meters. It is the largest v-pillar in lusier stadium. From 8:00 a.m. on May 9 to 2:00 a.m. on May 10, the hoisting continued. In the process of hoisting, three technicians on site are responsible for remote control of Jack to control the length of lifting rope to ensure the smooth rotation of v-pillar in the air; four assemblers are responsible for the bolt connection between the support and v-pillar base to ensure the final hoisting in place. Li Bai, chief engineer of the project, Ma Gaofeng, deputy project manager and other management personnel have been squatting at the site and dispatching at any time.

This is what the group photo of "class" looks like

"Grade" group photo is like this

It's like this after graduation

In the early morning of November 4, 2019 local time, the major construction node target was completed at lusell stadium, and the hoisting of 48 v-pillars of the main steel structure of the project was completed, laying a foundation for the subsequent important process of curtain wall and pressure ring installation. According to Liu Dawei, the project manager, in the process of v-pillar hoisting, due to the influence and restriction of the steel structure construction of the stands, 44 of them have been hoisted in late September, and the remaining 4 have been equipped with hoisting conditions. The leaders and experts of the project department consider the construction progress of the whole stadium, and decide to coordinate the construction site for the steel structure construction of the stands after discussion and consultation, so as to make v-pillar hoisting It took a month to complete the installation process, but in terms of the total construction period, it effectively saved 15 days for the construction of the whole project.

Recently, the most important construction period node of the main steel structure of the 2022 Qatar world cup main stadium lusail stadium project undertaken by China Railway Construction International Group is about to be closed, and the overall "saddle shaped" appearance is about to be formed. Pressure ring hoisting is the key process of the project, with tight construction period, difficult construction organization and high safety requirements. CRCC international overcomes the impact of the epidemic, strengthens personnel allocation and resource scheduling, and ensures the smooth implementation of the project.

Copyright © Zhejiang Wanhao Group Co., Ltd. All Rights Reserved.

Sitemap | Technical Support